1. Process Synthesis and Design

Our researches are mostly concerned with the design of optimal structures for

water-using networks, heat recovery and utility systems in chemical processes.

In recent years, we are also interested in developing:

(1) design and

maintenance strategies for control and instrumentation systems in industrial

plants,

(2) process integration methods for waste minimization and cleaner

production and

(3) optimal scheduling strategies for batch azeotropic

distillation networks.

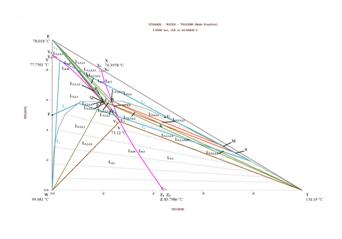

Batch azeotropic distillation network : Ethanol-water-toluene system;State-Task Network represents the order of operation(left);Operating line represents the mass balance and process condition(right).

2. Process Safety Assessment

The main thrust of our effort is to automate several widely-adopted safety assessment procedures. We have successfully integrated FTA/FMEA/HAZOP into a digraph-based generic software. Recently, we also have developed mathematical programs for designing multi-layer protective systems with optimal maintenance schedules.

Multilayer protective systems:general framework of a protected procsee(left);A CSTR

with multilayer protective system(right).

3. Fault Detection and Diagnosis

These issues are critical in enhancing operational safety in chemical plants. Our interests are diversified, e.g.

(1) the application of EKF, neural network, fuzzy logic and digraph in fault diagnosis

(2) the synthesis of optimal alarm logics

(3) the development of multi-variate run rules for statistical process control, etc.

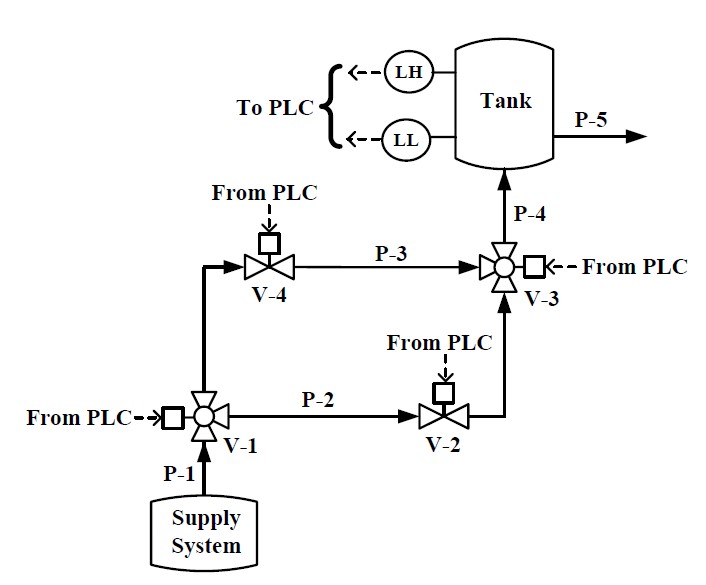

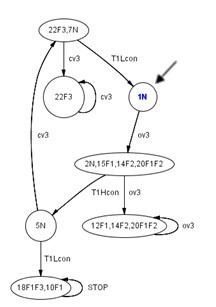

Fault evolution sequences:Flow diagram of a single-tank storage system with feed-forward level-control loop(left); The corresponding SDG model(right).

4. Batch Operations

It is our objective to develop a systematic approach to automatically generate the optimal schedule of operation steps (under normal or abnormal conditions) so as to achieve one or more specific production goal in any batch process. In a related study, we have developed test plans on the basis of discrete-event system (DES) theory in order to enhance diagnostic performance.

In one of the related research projects, we have developed test plans on the basis of discrete-event system (DES) theory in order to enhance diagnostic performance of batch processes.

5. Supply Chain Management

The management of a large network of interconnected production and transportation units is an important issue for the petrochemical industries. In recent years, we have developed a generic mixed-integer linear program (MILP) to synthesize the best multi-period planning strategy for any given petroleum supply chain to satisfy the specified supplies and demands.

Supply chain in petrochemical industries:A typical single-train BTX supply chain.